Understanding Your Options in Warehouse Lifting Equipment

In modern warehousing, choosing the right forklift truck can significantly impact efficiency, safety, and operational costs. Among the most widely used types are the manual hydraulic forklift truck and the all-electric stacker truck. While both serve the essential function of lifting and transporting pallets and materials, their performance characteristics, cost, and application scenarios differ considerably.

Choosing between these two types depends on factors like your warehouse size, frequency of use, load capacity requirements, and labor constraints. Let’s take a closer look at what sets them apart and how to determine which is the best fit for your operations.

Manual Hydraulic Forklift Trucks: Simple and Reliable

Basic Function and Structure

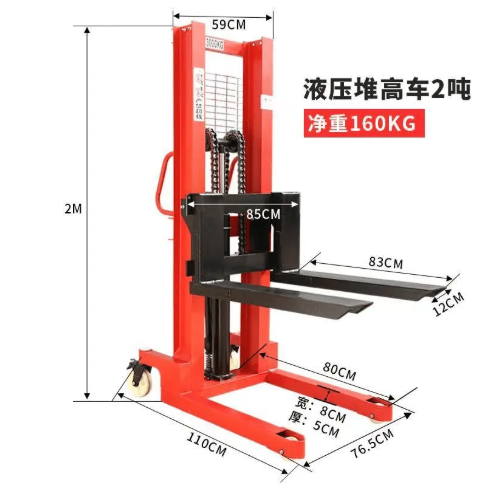

A manual hydraulic forklift truck, often referred to as a pallet jack or hand pallet truck, uses human force combined with a hydraulic system to lift and move loads. The operator pumps a handle to raise the forks and pulls or pushes the unit manually.

These forklifts are typically compact, easy to maintain, and well-suited for smaller warehouses or retail environments where heavy lifting isn’t a daily task.

Advantages of Manual Hydraulic Trucks

Manual models have very few electronic or mechanical components, which means they are highly reliable and inexpensive to maintain. They don’t require charging or fuel, making them ideal for environments with budget constraints or occasional material movement tasks.

In addition, their compact size allows for excellent maneuverability in tight spaces, such as narrow aisles or small loading docks. For operations that handle light loads or occasional pallet movement, the manual hydraulic forklift truck is often more than sufficient.

Limitations to Consider

Despite their simplicity, manual hydraulic forklifts are not suited for high-frequency, heavy-duty use. Repeated manual operation can lead to operator fatigue, reducing productivity and increasing the risk of workplace injuries. They are also limited in lifting height and typically cannot handle loads above 2,500 kg.

Moreover, manual models rely entirely on human effort, which can slow down operations in busier or larger-scale warehouses.

All-Electric Stacker Trucks: Power Meets Precision

How They Work

An all-electric stacker truck is powered by a battery and features motorized lifting and movement. These trucks are designed for more intensive warehouse operations, allowing users to lift heavy loads to higher elevations with minimal physical effort.

Electric stackers are typically equipped with advanced control systems, safety sensors, and ergonomic designs, making them a popular choice in larger facilities with high turnover and vertical racking systems.

Benefits of Going Electric

The key advantage of electric stacker trucks lies in their efficiency. They can significantly reduce manual labor, improve throughput, and minimize fatigue-related errors. The ability to lift loads to greater heights makes them ideal for multi-level storage systems, and many models offer programmable lifting speeds and safety mechanisms like overload protection.

Since these trucks are battery-operated, they also provide a cleaner and quieter alternative to gas or diesel-powered forklifts, making them more suitable for indoor use.

Furthermore, some modern electric stackers come with features such as touchscreen controls, regenerative braking, and energy-efficient lithium-ion batteries that reduce downtime and extend operational lifespan.

Challenges of Electric Stackers

On the downside, electric stackers come with higher upfront costs and require consistent battery maintenance. Charging infrastructure must be in place, and operations must plan for charging cycles to avoid downtime.

Their size can also be a limiting factor in smaller warehouses, where turning radius and storage space may be restricted.

Comparing the Two: Key Considerations

Load Capacity and Lifting Height

Manual hydraulic forklift trucks usually handle up to 2,000–2,500 kg and have a lifting height limited to a few inches off the ground. In contrast, electric stackers can often lift loads up to 3,000 kg and reach heights of over 5 meters, making them suitable for vertical racking.

Frequency of Use

For operations involving frequent pallet movements throughout the day, an electric stacker offers speed, consistency, and operator comfort. Manual options are better suited for occasional or low-volume use.

Warehouse Size and Layout

Smaller warehouses with tight aisle spacing may benefit from the nimble design of manual pallet trucks. However, larger facilities with wide aisles and tall storage racks will find the electric stacker’s power and reach far more advantageous.

Budget and Maintenance

Manual forklift trucks are cheaper upfront and require minimal upkeep. Electric stackers, while more costly, deliver better ROI in high-volume environments due to their efficiency and time-saving potential.

Labor and Ergonomics

Electric models dramatically reduce the physical strain on workers, promoting safer handling practices and reducing injury risk. If labor health and retention are a concern, investing in electric stackers can pay long-term dividends.

Case Scenarios: Which Truck Suits You Best?

Scenario 1: Small Warehouse or Retail Store

If your business runs a small warehouse, convenience store, or retail outlet where pallets are moved a few times a day, the manual hydraulic forklift truck provides a cost-effective solution with low maintenance needs.

Scenario 2: E-Commerce Fulfillment Center

In a high-volume, fast-paced environment like an e-commerce distribution center, speed and efficiency are critical. An all-electric stacker truck offers the lifting power, maneuverability, and consistency needed to keep up with rapid picking and shipping schedules.

Scenario 3: Cold Storage or Food Warehousing

Electric stackers perform better in temperature-controlled environments since they avoid emissions and allow precise control. Their low-noise operation is also beneficial in facilities where hygiene and worker comfort are priorities.

Environmental Considerations

While both types of forklift trucks have minimal environmental impact compared to gas or diesel alternatives, electric stackers take the lead in sustainability. They produce zero emissions and use rechargeable batteries, making them ideal for businesses focused on reducing their carbon footprint.

Some manufacturers are now offering solar-powered charging options or integrating smart energy management systems to further reduce electricity consumption.

The Verdict: Tailoring the Choice to Your Needs

When choosing between a manual hydraulic forklift truck and an all-electric stacker, there is no one-size-fits-all answer. Instead, it depends on your warehouse’s specific needs, operational volume, and long-term goals.

If your focus is on occasional, short-distance movement of standard pallets in confined areas, a manual truck is a straightforward and budget-friendly option. However, if productivity, lifting capacity, and worker ergonomics are essential, investing in an electric stacker will offer greater returns.

Warehouses that experience growth may even benefit from using both types—manual trucks for quick, light-duty tasks, and electric stackers for the heavy lifting.

FAQ

What maintenance does a manual hydraulic forklift truck require?

Regular checks of the hydraulic oil, wheel condition, and fork integrity are usually sufficient. Lubrication and visual inspections every few months will ensure smooth operation.

How long does the battery of an electric stacker truck last?

Depending on the battery type and usage intensity, a full charge can last from 4 to 8 hours. Lithium-ion batteries offer longer cycles and faster charging.

Are electric stackers suitable for outdoor use?

While some electric stackers can be used outdoors, they are generally optimized for indoor environments with flat, smooth surfaces. Outdoor use requires weatherproofing and larger wheels.

Can a small business afford an electric stacker?

Though the initial investment is higher, many suppliers offer financing plans. The improved efficiency and reduced labor costs can justify the expense over time.

Table of Contents

- Understanding Your Options in Warehouse Lifting Equipment

- Manual Hydraulic Forklift Trucks: Simple and Reliable

- All-Electric Stacker Trucks: Power Meets Precision

- Comparing the Two: Key Considerations

- Case Scenarios: Which Truck Suits You Best?

- Environmental Considerations

- The Verdict: Tailoring the Choice to Your Needs

- FAQ