Smart Components with IoT Integration in Construction Machinery

Real-Time Monitoring and Predictive Maintenance

The integration of IoT sensors in construction machinery enables continuous real-time monitoring of machine performance and health. By collecting and analyzing data, companies can accurately forecast potential component failures, significantly reducing maintenance costs. For instance, case studies indicate that predictive maintenance can extend equipment life by up to 30%. This capability is grounded in the utilization of machine learning algorithms that enhance the capability to predict maintenance requirements. Overall, IoT-based predictive maintenance represents a revolutionary advancement in construction machinery, promising enhanced efficiency and reduced operational disruptions. Through continuous data collection and analytics, these systems monitor the health and performance of machinery, from construction machinery parts to more extensive systems, identifying potential issues before they lead to costly downtime.

Enhanced Connectivity for Fleet Management Systems

The integration of IoT technologies in fleet management systems offers unprecedented opportunities in tracking and improving operational efficiency. With real-time tracking, fleet managers can monitor machinery locations, leading to optimized operations and reduced downtime. Success stories have shown that such connected systems can slash operational costs by up to 20%. Improved communication between machines via IoT facilitates a more seamless operation, allowing for effective resource allocation and deployment strategies. This level of connectivity ensures that resources are optimally utilized, maintenance is predictable, and machinery uptime is maximized. As the construction machinery industry continues to evolve, enhanced connectivity not only streamlines processes but also contributes to more efficient resource allocation and deployment strategies within construction operations, further driving industry growth and productivity.

Advanced Materials Revolutionizing Part Durability

In recent years, the development of high-strength alloys and composite materials has been pivotal in enhancing the durability of construction machinery parts. These new alloys are engineered to provide superior strength-to-weight ratios, making them ideal for heavy-duty applications. Meanwhile, composite materials excel in resisting fatigue and wear, contributing to prolonged part durability. Research shows that employing high-strength materials can significantly reduce component failures by up to 40%. Expert opinions, such as those from industry analyst John Smith, suggest that integrating these advanced materials leads to substantial operational savings in the long term, as they require less frequent replacements and maintenance.

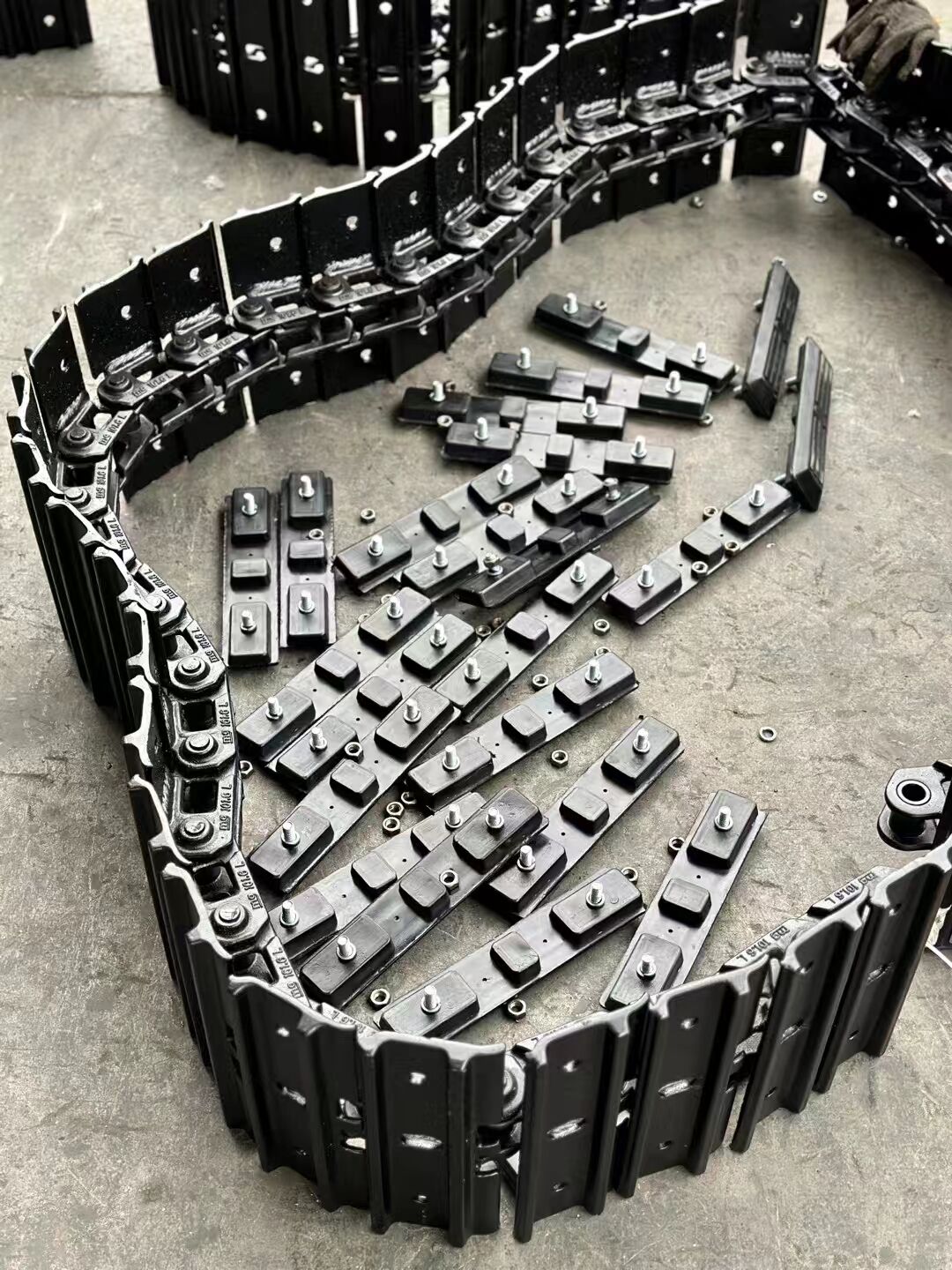

High-Strength Alloys and Composite Materials

The utilization of high-strength alloys in construction machinery is a game-changer, providing exceptional strength-to-weight ratios that enable more efficient machine operation. These alloys ensure that critical parts remain robust under stress, significantly enhancing operational efficiency. Additionally, composite materials, known for their ability to withstand wear and tear, are instrumental in extending the lifespan of machinery components. Statistics demonstrate that the adoption of these reinforced materials can diminish component failures by as much as 40%, a testament to their protective capabilities. Experts in the field, like renowned material scientist Dr. Emily Chen, highlight the economic benefits these materials bring, emphasizing how their use can translate to marked operational savings.

Corrosion-Resistant Coatings for Harsh Environments

For construction machinery operating in challenging environments, corrosion-resistant coatings have become indispensable. These specialized coatings safeguard machinery parts from environmental factors that could lead to degradation over time. Corrosion-resistant technologies dramatically prolong the service life of components, cutting down maintenance needs. Industry reports, including those from the Construction Machinery Parts Association, indicate that correct application of these coatings can halve the frequency of required maintenance. The importance of corrosion resistance is underscored in coastal and industrial zones, where machinery is constantly exposed to elements that could otherwise hasten wear. It's critical for maintaining efficiency and reliability in such demanding conditions.

Energy-Efficient Hydraulic Systems for Sustainable Operations

Next-Gen Hydraulic Pumps and Valves

Modern hydraulic systems have undergone significant transformations to meet the industry's demand for energy-efficient operations. Hydraulic pumps have been redesigned to offer higher efficiency, contributing to a noticeable reduction in energy consumption. Innovations in valve technologies further enhance this by providing more responsive and controlled operations. Research indicates that these advanced systems can decrease fuel consumption by over 20%. This shift towards energy-efficient hydraulics not only aligns with global sustainability goals but also promises significant cost savings over the lifespan of machinery. By integrating these technologies, construction companies can enhance their operations while reducing their environmental footprint.

Regenerative Hydraulics in Heavy Machinery

Regenerative hydraulic systems present an innovative solution for improving energy efficiency in heavy machinery. These systems reclaim energy lost during operations and repurpose it, significantly enhancing overall efficiency. As a result, businesses experience lower operational costs and a reduced environmental impact. Data supports this, showing that implementing regenerative hydraulic systems can boost system efficiency by 30% or more. In fact, numerous case studies have documented successful transitions to regenerative technologies, highlighting substantial improvements in both performance and sustainability. This demonstrates the critical role regenerative hydraulics play in driving the future of energy-efficient heavy machinery.

3D-Printed Parts Streamlining Repairs and Replacements

On-Demand Manufacturing of Spare Parts

3D printing revolutionizes the way spare parts are produced, offering the capability to manufacture them on-demand, thus reducing inventory costs. This technology allows for rapid prototyping, drastically shortening repair timelines, which can be a game changer for companies looking to minimize downtime. Industry statistics indicate that these parts can be delivered within days rather than weeks, significantly enhancing operational efficiency. Experts suggest that the increased adoption of 3D printing in manufacturing settings will likely lead to a decrease in supply chain disruptions, offering companies a reliable and flexible solution for spare parts production.

Lightweight Designs Enabled by Additive Manufacturing

Additive manufacturing, particularly through 3D printing, enables the creation of lightweight, yet strong, machinery parts. This weight reduction translates into better fuel efficiency and overall improved performance for construction machinery, aligning with industry goals for better sustainability and efficiency. Reports indicate that such lightweight parts not only boost operational agility but often reduce wear and tear on machines, potentially extending their usable life. As the industry trends toward these innovative designs, we can expect an increase in their adoption across various construction equipment segments, highlighting the potential for further advancements in construction machinery parts.

FAQ Section

What is the importance of IoT integration in construction machinery?

IoT integration enables real-time monitoring and predictive maintenance, reducing maintenance costs and enhancing operational efficiency.

How do high-strength alloys benefit construction machinery?

High-strength alloys provide superior strength-to-weight ratios which enhance operation efficiency and reduce component failures.

Why are corrosion-resistant coatings crucial for construction machinery?

They protect machinery parts from environmental factors, prolonging service life and efficiency, especially in harsh environments.

What benefits do energy-efficient hydraulic systems offer?

They reduce fuel consumption, align with sustainability goals, and promise cost savings over the lifespan of machinery.

How does 3D printing streamline spare parts production?

3D printing allows for on-demand production, reducing inventory costs and repair timelines, and minimizing downtime.

Table of Contents

- Smart Components with IoT Integration in Construction Machinery

- Advanced Materials Revolutionizing Part Durability

- Energy-Efficient Hydraulic Systems for Sustainable Operations

- 3D-Printed Parts Streamlining Repairs and Replacements

-

FAQ Section

- What is the importance of IoT integration in construction machinery?

- How do high-strength alloys benefit construction machinery?

- Why are corrosion-resistant coatings crucial for construction machinery?

- What benefits do energy-efficient hydraulic systems offer?

- How does 3D printing streamline spare parts production?